C Cindezela Isivinini Esiphezulu

Izici zokusebenza

1. Uhlaka lwenziwe ngensimbi ephezulu enamandla. Ngemuva kokukhululeka kwangaphakathi kwengcindezi, okokusebenza kuzinzile futhi ukunemba kuhlala kungashintshi, okulungele kakhulu ukukhiqizwa kokugxivizwa okuqhubekayo;

2.Umhlahlandlela wesitimela esihamba phambili, isakhiwo esisodwa sensika, usebenzisa i-zero error ball bearing ukumiselela isakhiwo sendabuko se-sliding, ukuze wehlise ukungqubuzana okunamandla, futhi ubambisane nokuthambisa okuphoqelelwe ukunciphisa ukushuba okushisayo nokufeza ukunemba okuphezulu ;

3.Idivaysi yebhalansi eseceleni eguqukayo iyakhethwa ukunciphisa ukudlidlizela, ukuze umshini ube nokunemba okuhle nokuqina;

4. Ukulungiswa kwesikhunta mathupha, ngokubonisa ukuphakama kwesikhunta nedivayisi yokukhiya ingcindezi kawoyela, kulula ukusebenza kokulungiswa kwesikhunta;

5.Ukulawulwa komshini womshini womuntu, isibonisi sephutha lokuqapha uhlelo lwesibalo, okulula ukusebenza;

Specification

Izinzuzo

Umhlahlandlela wesilayidi

Inzuzo 1: Isitimela sesilayidi sisebenzisa "ukucisha imvamisa ephezulu" kanye "nenqubo yokugaya ujantshi":

Ukucima imvamisa ephezulu: ubunzima bufinyelela ngenhla kwe-hrc48,

Inqubo yokugaya isitimela: ukuphela komhlaba kungafinyelela kuRa0.4, ukubabazeka kuphakeme njengokufika ku-0.01mm / m2, ngokuvamile okuyi-03mm / m2.

Izinzuzo: ukugqoka okuncane, ukucacisa okuphezulu, isikhathi eside ukugcina ukunemba nokwenza ngcono impilo yensizakalo yabashonile.

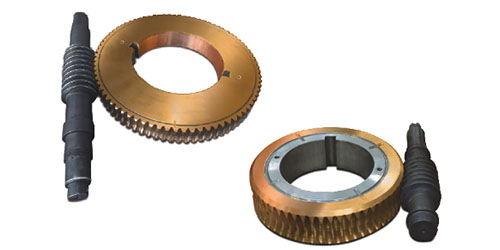

Igiya lesibungu

Inzuzo 2: I-Turbine enokulungiswa okuphezulu kwe-slide die isebenzisa amandla aphezulu ithusi le-alloy material: Tin Phosphorus Bronze (zqsn10-1)

Uma kuqhathaniswa nesihlalo sebhola se-nodular cast iron esetshenziswa amafemu ajwayelekile

Izinzuzo:amandla nokuqina kokuqina kuthuthukiswa ngokufanayo. Amathuba okuquleka ancishiswe kakhulu enqubeni yokulungiswa kokufa, Impilo yesevisi enwetshiwe

Isokhethi yebhola

Inzuzo 3: Izinto zokuhlala esihlalweni sebhola: isihlalo sibhola sintered TM-3 sethusi sebhola, isokhethi lebhola lomkhiqizi ojwayelekile liyinsimbi ye-nodular cast.

Izinzuzo:isihlalo sebhola le-TM-3 lethusi le-alloy yethusi elinamandla acindezelayo ebusweni we-1000kgf / C m2. Ngenkathi yokugxivizwa, amathuba okuquleka ancishiswe kakhulu futhi nempilo yesevisi yandiswa

Umkhono wethusi

Inzuzo 4: Yonke imikhono yethusi ye-punch press yenziwe ngeTin Phosphorus Bronze zqsn10-1, kanti i-bc6 (zqsn 6-6-3) impahla yethusi isetshenziswa abakhiqizi abajwayelekile

Izinzuzo: amandla aphakeme izikhathi eziyi-1.5 kunaleyo ye-bc6 yethusi, ngamandla aphezulu, ukugqoka okuncane nesikhathi sokugcina esinemba ngokunemba

Thimble

Inzuzo 5: Indandatho yemikhono, indandatho ethintana nophawu lukawoyela, inqubo "yokugaya ebusweni" + "yenqubo ye-chromium plating (CR)"

Izinzuzo: ukuphela komhlaba kuphakathi kukaRa0.4 noRa0.8, akulula ukuvuza uwoyela lapho uxhumana nophawu lwamafutha, kanti ingaphezulu ligaxiwe nge-chromium (CR)

Inqubo, ubulukhuni obufinyelela kuma-degree angama-hrc48, ukuqinisekisa ukuthi ukusetshenziswa kwesikhathi eside akugqoki, impilo yensizakalo ka-oyela yinde

I-Crankshaft

Inzuzo 6: I-crankshaft yenziwe nge-alloy ephezulu engu-42CrMo, kanti i-crankshaft yabakhiqizi jikelele yenziwe ngensimbi engu-45

Izinzuzo: amandla aphakeme izikhathi eziyi-1.3 kunaleyo yensimbi engama-45, impilo yesevisi yinde, futhi nethuba lokwephula i-crankshaft lincishisiwe (ngokuqinile ngokuqinisa, ukwelashwa ukushisa, ukuthola iphutha, ukucubungula, ukuhlolwa, njll.) ukuqinisekisa Zonke izinhlobo zezinkinga zekhwalithi enqubeni yokukhiqiza ye-crankshaft ziyagwenywa ukuqinisekisa ikhwalithi ye-crankshaft.

Ukubhabha

Inzuzo 7: Umshini ojwayelekile uvule iphuzu elilodwa futhi uvule iphoyinti eliphindwe kabili le-punch cindezela, ipayipi elijwayelekile lokucindezela uwoyela lithatha Φ 6 (abanye abakhiqizi ngokuvamile basebenzisa Φ 4), ipayipi eliphakathi nendawo elikhulu lokucindezela uwoyela wokucindezela ipayipi lithatha Φ 8

Izinzuzo: ipayipi elide, ububanzi obukhulu akulula ukuvimba, ukuphuka, ukuqinisekisa ukuphepha kukawoyela wokuthambisa, bushelelezi

Igiya & shaft shaft

Inzuzo 8: I-shaft yegiya isebenzisa inqubo yokuqeda imvamisa ephezulu ukuqinisekisa impilo yenkonzo ende ngaphandle kokuguga