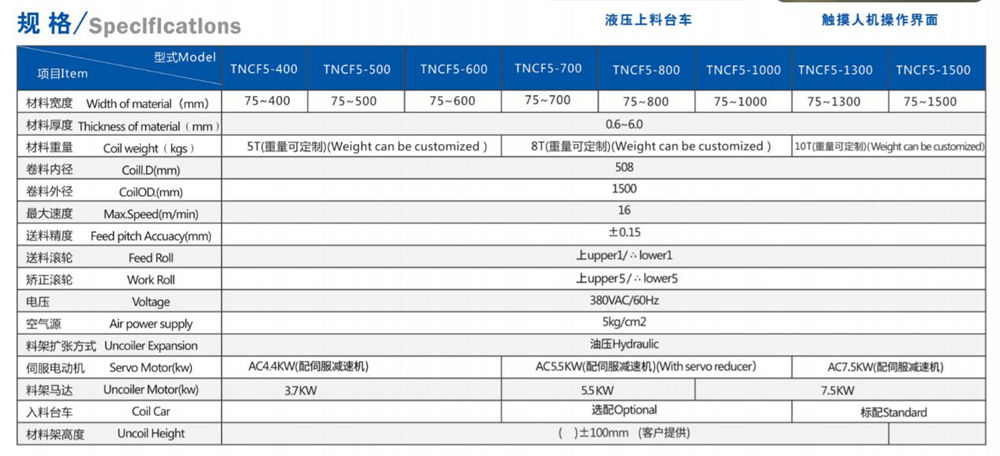

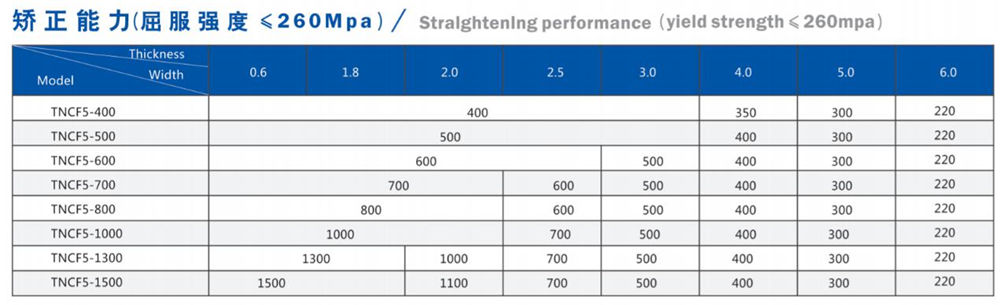

Umshini we-TNCF5-series 3IN INC Servo Feeder

Isici

1. Ukulungiswa kokulinganiswa kwamukela ukufundwa kwemitha yokubonisa yedijithali;

2.Isikulufa sokunemba okuphezulu siqhutshwa wwheel handwheel enhle nenegethivu yokulawula ukulungiswa kobubanzi;

3. Ukuphakama kolayini wokudla kulungiswa ngamakheshi aqhutshwa yimoto;

4. Isetshenziswa ekuvimbeni i-roller eziyize ishidi lezinto ezibonakalayo;

5. Ukondla i-roller nokulungisa i-roller kwenziwa ngensimbi ephezulu ethwala insimbi (ukwelashwa okuqinile kwe-chromium plating);

6.Umshini wokucindezela umfutholuketshezi;

7. Imoto yegiya ishayela idivaysi yekhanda lokudla yesondo elicindezelayo;

8. Umshini wekhanda we-Hydraulic othomathikhi wokudla;

9.Umshini we-Hydraulic head head;

10. Uhlelo lokudla lilawulwa uhlelo lweMitsubishi PLC;

11. Ukunemba kokuphakelwa kulawulwa yi-Yaskawa servo motor kanye nokunemba okuphezulu kwe-servo reducer yamaplanethi;

Isingeniso

Ngenxa yokuthuthuka okuqhubekayo kobuchwepheshe, imishini yensimbi ye-punch ne-punch isetshenziswa kabanzi. Ukusetshenziswa kwemishini ye-punch peripheral kungathuthukisa ukusebenza kahle kokukhiqiza futhi kunciphise nezindleko zabasebenzi, ngakho-ke kuyathandwa ngabakhiqizi. Isisetshenziswa semikhawulo se-punch sihlukanise okuphakelayo, i-rack yezinto ezibonakalayo, umshini wokuqondisa, amabili kumshini owodwa wokuqondisa, amathathu kulayini owodwa wokulungisa i-rack. Namuhla sizokwethula kafushane abathathu bohlelo olulodwa lokudla.

1 Gcina isikhala

Umugqa wokukhiqiza wokunyathela ufaka i-rack ebonakalayo, umshini wokulinganisa nomshini wokudla. Uma le mishini emithathu izimele, ivolumu yomshini ngamunye ayincane. Ngaphezu kwalokho, ukuze kuqinisekiswe ukukhiqizwa okujwayelekile, kufanele kube khona indawo yokulinda ebonakalayo phakathi komshini nomshini. Ngakho-ke, indawo yaphansi yomugqa wokukhiqiza ingacatshangwa. Ngokuvamile, kunesikhala esincane esisele ngemuva kokuthi imishini ixhunywe ezintanjeni, okwenza kube nzima kakhulu ukuthi opharetha bahambe ngeNzuzo. Abathathu kokuphakelayo okukodwa bahlanganisa imishini emithathu ibe munye. I-fuselage icwecwe, futhi indawo yaphansi yehliswe ngaphezu kwengxenye uma iqhathaniswa nolayini wokukhiqiza ozimele ohlukile ozimele, ukuze indawo yokusebenzela isetshenziswe ngokugcwele, futhi opharetha banendawo yokusebenza eyanele, engeke idale ukungasebenzi kahle, futhi wandise ukuphepha kokukhiqizwa kwesitembu.

2 Ukonga izisebenzi namandla aphezulu okusebenza

Abathathu kokuphakelayo okukodwa badinga umuntu oyedwa kuphela ukuqedela ukondla, ukondla, ukudweba, ukulungisa iphutha, ukuhlolwa kwesikhunta nokunye ukusebenza, futhi isikhathi esichithwe asisincane. Kodwa-ke, uhlobo lwendabuko oluhlukile noluzimele ludinga isethi ngayinye ukuthi ifakwe umuntu oyedwa, futhi kwesinye isikhathi idinga ukusizana ukuqedela lo msebenzi, ongakulungeli ukonga abasebenzi nokwenza ngcono amandla okusebenza.

Ukusebenza okulula nokunemba okuphezulu

Abathathu kokuphakelayo okukodwa basebenzisa uhlelo lokulawula ikhompyutha. Umsebenzi wokusebenza ugxile ngokuphelele kusibambo sekhonsoli nolawulo. Umuntu oyedwa angavele aqedele ukusebenza, okwenziwe ubuntu kakhulu. Okuphakelayo okuthathu kokukodwa kungasetha ubude bokudla ngokungafanele, kuthambise ekugcineni kwekhoyili ukwenza lula idatha ukuthi ingene ku-roller, futhi imoto ishayela imishini yengalo ecindezelayo ukuvimbela ikhoyili ukuthi ingakhululeki. Imishini yokuqondisa nokondla itholakala kuraki owodwa, futhi asikho isikhawu phakathi kwezisekelo, eziqinisekisa ngokusobala ukuvumelanisa komsebenzi wazo. Kunganciphisa amaphutha okondla nokulungisa, futhi kufinyelele esicelweni sokunemba okuphezulu, okuphephile futhi okuzinzile.

4 Izinga eliphakeme lesinyathelo nokusetshenziswa okubanzi

Abathathu kokuphakelayo okukodwa kunesakhiwo esihlanganisiwe, esivumelana nohlelo lokukhiqiza uhlelo lokuqala nokubambisana. Ukusuka ekulayisheni, ekugoqeni nasekululameni nasekuphakeleni, iqoqo lezinqubo lingaqedwa ngemizuzu embalwa ngumuntu oyedwa. Kulula ukusebenza futhi kusebenza kakhulu. Ifanele ukugxivizwa okuqhubekayo kwensimbi ehlukahlukene, ukunyathela, i-elekthronikhi, izinto zikagesi, amathoyizi nezingxenye zezimoto.

Izinga lokwehluleka okuphansi nempilo ende

Abathathu kokuphakelayo okukodwa kunenani eliphansi lokwehluleka nempilo ende yokusebenza