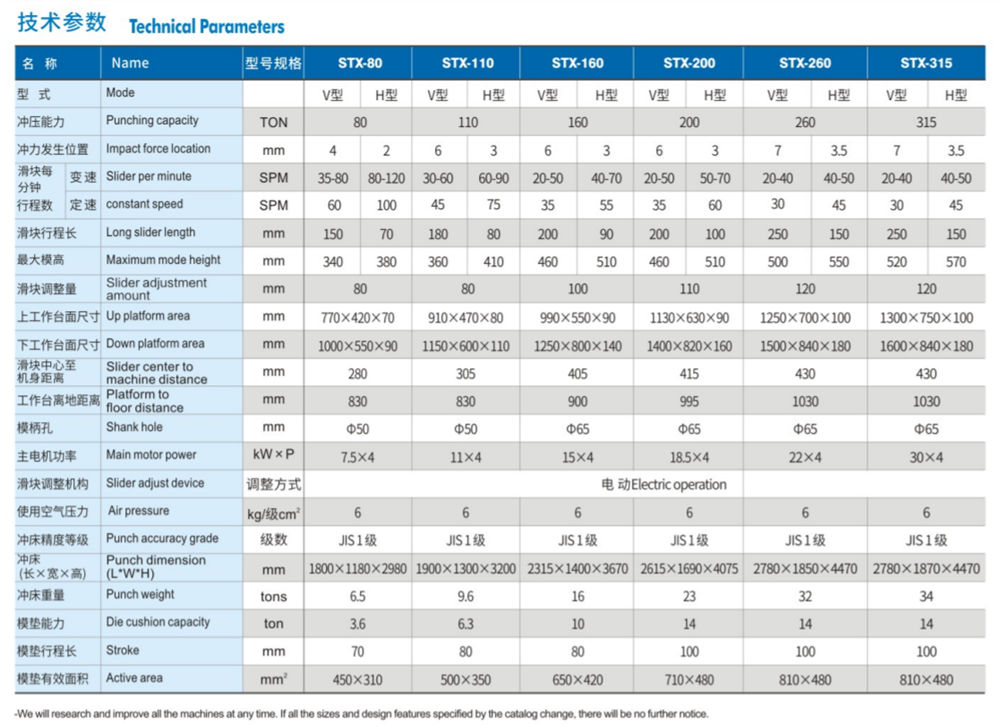

Uchungechunge lwe-STX C Uzimele owodwa we-Crank Mechanical Press

Main ukusebenza izici:

Ukuqina komzimba (ukusonteka) 1/6000.

Sebenzisa i-pneumatic wet clutch brake, ukuvikelwa kwemvelo, akukho ukungcola, umsindo ophansi, impilo ende yokusebenza.

Isilayida sisebenzisa izindlela ezimbili zomhlahlandlela ezinamacala ayisithupha, futhi isiqondisi sesilayida sisebenzisa "ukuqina kwemvamisa ephezulu" kanye "nenqubo yokugaya ujantshi": ukugqoka okuphansi, ukucacisa okuphezulu, isikhathi sokugcinwa ngokunemba isikhathi eside, nempilo yesikhunta ethuthukisiwe.

I-crankshaft yenziwe ngezinto ezinamandla amakhulu ze-alloy 42CrMo, enamandla aphindwe ka-1.3 kunensimbi engama-45 futhi inempilo yenkonzo ende.

Umkhono wethusi wenziwe nge-tin-phosphorus bronze ZQSn10-1, amandla ayo aphindwe izikhathi eziyi-1.5 kunaleyo ejwayelekile ye-BC6 yethusi.

Ukusetshenziswa kwensiza yokuvikela ukucindezela ngokweqile kakhulu kwe-wokubacindezela kungavikela ngempumelelo impilo yesevisi yesibhakela bese iyafa.

I-valve ejwayelekile yaseJapan ye-SMC elawula i-valve, i-lubricator, isihlungi somoya.

Amabheringi ejwayelekile aseJapan waseJapan NSK nezimpawu zaseJapan zeNOK.

Ukumiswa okujwayelekile kwe-German Siemens PLC, i-Nokia touch screen, i-Nokia motor,

Akuphoqelekile isikhunta isiguqo (air isiguqo).

Ukumiswa okujwayelekile

Ukumiswa okujwayelekile

| Idivayisi yokuvikelwa ngokweqile kwe-Hydraulic |

| Idivayisi yokulungiswa kwesilayidi mathupha (ngezansi kwe-ST60) |

| Idivayisi yokulungisa i-slider kagesi (ngenhla kwe-ST80) |

| Imvamisa eguquguqukayo yesivinini semoto (isivinini esiguquguqukayo) |

| Isibonisi sokuphakama kwesikhunta (ngezansi kwe-ST60) |

| Isibonisi sokuphakama kwesikhunta sedijithali (ngaphezulu kwe-ST80) |

| Isilayida nesikhunta ibhalansi yedivayisi |

| Isilawuli se-cam esizungezayo |

| Isibonisi se-Crankshaft angle |

| Ikhawunta kagesi |

| Isixhumi somthombo womoya |

| Idivayisi yokuvikelwa kokuwa kwezinga ezimbili |

| Idivayisi yokushaya umoya |

| Izinyawo zemishini ezothusayo |

| Isixhumanisi esibekiwe sedivayisi yokuthola ukulethwa okungalungile |

| Amathuluzi wokulungisa kanye nebhokisi lamathuluzi |

| Idivayisi enkulu yokuguqula imoto |

| Idivayisi yokuvikela ukuphepha kwe-Photoelectric |

| Amandla okuphuma |

| Idivayisi yokugcoba ugesi kagesi |

| Isikrini sokuthinta (pre-break, pre-load) |

Ukucushwa Okungakhethwa

| Womoya kudivayisi isikhunta pad |

| Ukushintshwa kwezinyawo |

| Idivayisi yokushintsha esheshayo (die lifter, die clamper |

| Noma isikhunta shifter) |

| Ingxenye ephezulu yokushaya idivayisi yesilayida |

| Okuphakelayo (umoya, imishini kanye ne-NC) |

| Ukulinganisa umshini |

| Isiphathimandla |

| Isikhunta die ukukhanyisa idivayisi |

| Umugqa |

| Idivayisi yokugcoba uwoyela omncane |

Izinzuzo

Umhlahlandlela wesilayidi

Inzuzo 1: Isitimela sesilayidi sisebenzisa "ukucisha imvamisa ephezulu" kanye "nenqubo yokugaya ujantshi":

Ukucima imvamisa ephezulu: ubunzima bufinyelela ngenhla kwe-hrc48,

Inqubo yokugaya isitimela: ukuphela komhlaba kungafinyelela kuRa0.4, ukubabazeka kuphakeme njengokufika ku-0.01mm / m2, ngokuvamile okuyi-03mm / m2.

Izinzuzo: ukugqoka okuncane, ukucacisa okuphezulu, isikhathi eside ukugcina ukunemba nokwenza ngcono impilo yensizakalo yabashonile.

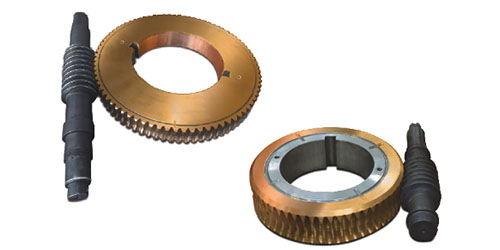

Igiya lesibungu

Inzuzo 2: I-Turbine enokulungiswa okuphezulu kwe-slide die isebenzisa amandla aphezulu ithusi le-alloy material: Tin Phosphorus Bronze (zqsn10-1)

Uma kuqhathaniswa nesihlalo sebhola se-nodular cast iron esetshenziswa amafemu ajwayelekile

Izinzuzo:amandla nokuqina kokuqina kuthuthukiswa ngokufanayo. Amathuba okuquleka ancishiswe kakhulu enqubeni yokulungiswa kokufa, Impilo yesevisi enwetshiwe

Isokhethi yebhola

Inzuzo 3: Izinto zokuhlala esihlalweni sebhola: isihlalo sibhola sintered TM-3 sethusi sebhola, isokhethi lebhola lomkhiqizi ojwayelekile liyinsimbi ye-nodular cast.

Izinzuzo:isihlalo sebhola le-TM-3 lethusi le-alloy yethusi elinamandla acindezelayo ebusweni we-1000kgf / C m2. Ngenkathi yokugxivizwa, amathuba okuquleka ancishiswe kakhulu futhi nempilo yesevisi yandiswa

Umkhono wethusi

Inzuzo 4: Yonke imikhono yethusi ye-punch press yenziwe ngeTin Phosphorus Bronze zqsn10-1, kanti i-bc6 (zqsn 6-6-3) impahla yethusi isetshenziswa abakhiqizi abajwayelekile

Izinzuzo: amandla aphakeme izikhathi eziyi-1.5 kunaleyo ye-bc6 yethusi, ngamandla aphezulu, ukugqoka okuncane nesikhathi sokugcina esinemba ngokunemba

Thimble

Inzuzo 5: Indandatho yemikhono, indandatho ethintana nophawu lukawoyela, inqubo "yokugaya ebusweni" + "yenqubo ye-chromium plating (CR)"

Izinzuzo: ukuphela komhlaba kuphakathi kukaRa0.4 noRa0.8, akulula ukuvuza uwoyela lapho uxhumana nophawu lwamafutha, kanti ingaphezulu ligaxiwe nge-chromium (CR)

Inqubo, ubulukhuni obufinyelela kuma-degree angama-hrc48, ukuqinisekisa ukuthi ukusetshenziswa kwesikhathi eside akugqoki, impilo yensizakalo ka-oyela yinde

I-Crankshaft

Inzuzo 6: I-crankshaft yenziwe nge-alloy ephezulu engu-42CrMo, kanti i-crankshaft yabakhiqizi jikelele yenziwe ngensimbi engu-45

Izinzuzo: amandla aphakeme izikhathi eziyi-1.3 kunaleyo yensimbi engama-45, impilo yesevisi yinde, futhi nethuba lokwephula i-crankshaft lincishisiwe (ngokuqinile ngokuqinisa, ukwelashwa ukushisa, ukuthola iphutha, ukucubungula, ukuhlolwa, njll.) ukuqinisekisa Zonke izinhlobo zezinkinga zekhwalithi enqubeni yokukhiqiza ye-crankshaft ziyagwenywa ukuqinisekisa ikhwalithi ye-crankshaft.

Ukubhabha

Inzuzo 7: Umshini ojwayelekile uvule iphuzu elilodwa futhi uvule iphoyinti eliphindwe kabili le-punch cindezela, ipayipi elijwayelekile lokucindezela uwoyela lithatha Φ 6 (abanye abakhiqizi ngokuvamile basebenzisa Φ 4), ipayipi eliphakathi nendawo elikhulu lokucindezela uwoyela wokucindezela ipayipi lithatha Φ 8

Izinzuzo: ipayipi elide, ububanzi obukhulu akulula ukuvimba, ukuphuka, ukuqinisekisa ukuphepha kukawoyela wokuthambisa, bushelelezi

Igiya & shaft shaft

Inzuzo 8: I-shaft yegiya isebenzisa inqubo yokuqeda imvamisa ephezulu ukuqinisekisa impilo yenkonzo ende ngaphandle kokuguga